All-Grain #2

- Posted by Josh on September 02, 2008 at 9:12pm

- Categories: All-Grain, Commercial Brews, Homebrews, Pictures

- No Comments »

The New Rig

My second batch of all-grain beer was brewed using a new system. I now have a 10-gallon mash/lauter tun.

Before my setup is complete, I still have to convert my kettle into a hot liquor tank though. This step will involve drilling a hole in the side/bottom of the kettle and installing a valve/stopcock with a faucet. This way the water can be drawn via gravity through a tube into the mash tun and avoid splashing. This past batch, I had to pour the water from the kettle into the tun. This involves splashing which generally means hot-side aeration, and hot-side aeration generally leads to oxidation in the finished product.

Hot-side aeration is when warm wort is aerated. Splashing is but one way to aerate. Oxidation in the water is usually driven off during the boil (which occurs after the mash to extract bitter compounds from the hops). But when the water/wort is over 80 deg.F, the oxygen entering the wort from aeration can bond with other compounds. These oxidized compounds are not driven off during the boil. When the beer is done fermenting and is aging, that is when the oxygen can come free of these compounds. At that point, your beer becomes oxidized. The best way to prevent off flavors from oxidation in my particular case will be to drink it all really quickly, before the oxidized wort compounds have a chance to release the oxygen into the aging beer! :)

So here is a picture of the mash/lauter tun. As you can see, it is a round, ten-gallon, plastic cooler. Also notice the metal spout/valve at the bottom which was the main investment when converting this thing into a mash/lauter tun:

If you are wondering why the lid appears to be silver, it’s because of that magical substance known as duct tape! The cooler belonged to my father-in-law. The lid could not be found. So I fashioned one using two inches of polystyrene (a good insulator to prevent heat from the mash from escaping out of the top) cut into discs and glued & duct taped together. The handle to remove the lid (because it is a nice, tight’n’snug fit) is a piece of rope. You can see the knots and washers on the bottom of the lid that keep it in place:

If you look down into the mash tun you see the lautering end – the manifold:

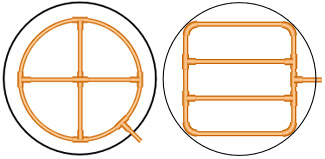

I built the manifold from a few dollars worth of CPVC fittings. Most people fashion the manifold into a ring or into a grill:

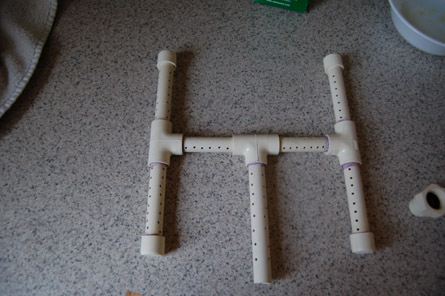

The ring isn’t really an option with CPVC because the curvature is hard to do. The grill would have been better, but I can always build one like this later: I have plenty of left-over 1/2 inch CPVC tubing and PVC primer and cement, and the elbows and T’s are really cheap (like a quarter or less each). Besides, mine looks kind of like an ‘H’ for Hump’s!

The manifold works thanks to small holes drilled into it (you could cut slits into it with a narrow saw, too, but I preferred the drill approach):

After the mash is completed, the sugar is rinsed from the grains and out the valve at the bottom, which will be fitted to a tube running to the bottom of the kettle. This process is known as lautering. My method is to use a batch sparge. In this method, instead of slowly drawing off the wort and slowly adding the sparge water to keep the water level even, I simply add all of the hot sparge water to the cooler and then open the valve. Before running the wort into the kettle, you draw the first 2-3 quarts and recirculate it (i.e. pour it back on top, but gently so as not to disturb the grains beneath). The first couple of quarts contain pieces of grain and husk. But after drawing off the first few quarts, the grains will have settled into a grain bed that acts as an effective filter to prevent pieces of grain and husk from getting into the kettle.

What I’ve learned from my mini-mash batches (and this batch was no exception): the hard part is temperature control. Once you get used to your system, it isn’t so bad, but this was the first time I’ve ever used this rig. Unfortunately, I did a poor job of reaching my desired temperature for the saccharification rest. The trick is to heat your mash water to the right temperature so that when you add it to the tun and the grains, it will equalize out to the rest temperature. I heated the water up to 165 deg. Fahrenheit, hoping to hit a rest temperature of 156. It turns out, I should have heated the water up to more like 177. I tried adding some boiling water to raise the mash temperature, but I only got to about 152. Some spots in the mash were as cool as 148, others as warm as 156 – about 152 average. I couldn’t add anymore boiling water or else run the risk of having too thin of a mash (which results in much slower conversion and could actually raise the pH too close to neutral so that the enzymes that convert starches to sugar are no longer active). A mash temperature of 152 means a little bit drier of a beer with less residual sweetness. Hopefully the choice of yeast (Wyeast 1968 London ESB Yeast) will offset this since it is a less attenuative breed.

Another total buzkill was that my hydrometer broke right before I started brewing. So, as of now, I do not actually know how well my first batch went with regards to efficiency (i.e. how much sugar was actually extracted from the grains – which is easily measured via a hydrometer in the form of specific gravity of the wort). I kept a sample of the wort so that I can measure the OG once I buy a new hydrometer, which won’t be until Thursday.

But I must have done okay, because the yeast are really chewing on it. My first all-grain batch, Hump’s Itsy Bitsy Bitter, didn’t produce much churn during fermentation due to the low original gravity. This beer, Hump’s Itsy Bitsy Brown (a Southern English Brown Ale, designed to be a modest 3.6% abv), is producing much more fervor from the magical little creatures.

House Brews

Speaking of other homebrews, Hump’s Imperial ESB is about gone. It went nearly flat, disconnected from CO2 while I was sampling commercial brews over the past couple of weeks (a 12-pack sampler of Magic Hat’s Summer brews). Tomorrow it will have been completely “reinvigorated”, and I’ll push it to bottles (or at least some of it – I think there is about one gallon remaining).

Hump’s Honey Nut Ale will be absolutely delicious. I racked it into keg #3 (yes, I acquired another keg) this past weekend, and it was so sublime. For those that don’t following along (or simply don’t remember from the last post), this batch is a “Nut Brown Ale” – in this case, literally with nuts. I added 3/4 pound of chopped, roasted nuts: mostly almonds, a good bit of pistachios, and a little bit of pine nuts.

The nuts did an amazing number filling the beer with an excellent nuttiness. The fats in the nuts even help the mouthfeel, giving it more body and silken texture. If I had to guess without knowing, I’d likely have guessed peanuts. On some level, the fact that the actual varieties of nuts used can’t be readily distinguished (at least by my palate) is somewhat disappointing. But not really. The finished product is really quite nice, so I really don’t have room to complain. It isn’t yet being force carbonated because I’m trying to “unflatten” the other two beers (as mentioned above, they were disconnected from the tank and lost some of their gassiness). Tomorrow, I’ll hook up the new keg to the tank and crank the pressure so I can have my first pint this weekend.

Magic Hat, Weyerbacker, and Stone

Speaking of commercial brews, Magic Hat, a well-known microbrewery in Vermont, is now available in Georgia. The mixed-up 12-pack I bought contained four different varieties:

- #9 – This is a really nicely done fruit beer: an apricot pale ale. It isn’t quite as nice as Dogfish Head’s ApriHop, but I do believe that Magic Hat made theirs first. That makes them the pioneer for this blend of flavors, and they did a good job. Dogfish Head’s approach is a little bit less fruit and a good bit more hops, which results in a better overall beer, but much less apricot – so some folks, particularly those with an aversion to really hoppy beers and those that really like apricot, may prefer the original from Magic Hat.

- Circus Boy – This was a decently done beer, too. This one is a hefeweizen flavored with lemongrass. The too flavors complement one another quite well making for a very decent wheat beer.

- Odd Notion (Summer 08) – This one didn’t quite hit the mark. It is billed as a Mild Ale, but is much harsher and less well-rounded than authentic examples of the style. The roastiness is a little too high, giving the beer a touch of acridity. The beer also had too many suds. A lower level of carbonation would have likely gone a long way in helping bring out the flavors of the beer. After all, many authentic milds from across the pond are cask-conditioned (thus having very little carbonation). Overall, it isn’t a bad beer – but not a really good one either.

- Hocus Pocus – This one is an odd one for sure. It is an American wheat beer, but has surprisingly more bittering hops than one would expect from the style. I actually enjoyed the beer – it is light and drinkable. But like the Odd Notion, it was overcarbonated. The body was way too thin, too. The flavor was bready with a firm, earthy bitterness. I mentioned in my notes at RateBeer.com that it was strangely familiar to me. After aging, my Itsy Bitsy Bitter shared quite a lot in common with this one. I also noted in my write-up how interesting that both of these two brews would be so far from style as to meet in an otherwise unknown middle ground. For the record, I think my bitter was further from style, but – from a purely hedonistic perspective – I enjoyed it more. Screw the style guidelines!

Another brewery that is only recently available in Georgia is Weyerbacher. I am still looking forward to snagging more of their beers – particularly the Double Simcoe IPA.

More to look forward to: this month (September 2008), Stone Brewing becomes available to our fair state. I’ve even seen the list of kegs that the Taco Mac in midtown is expecting, and it is most impressive. They are having a Stone Brewing beer dinner later this month, and I bet it will be absolutely phenomenal. I’ve had many of Stone’s brews, but I am very much looking forward to having more. Numerous great releases are expected to arrive in this state. I’m particularly anxious to get my hands on this year’s Vertical Epic, on some Oaked Arrogant Bastard, and on a bottle of their 12th Anniversary release: a bitter chocolate oatmeal stout.